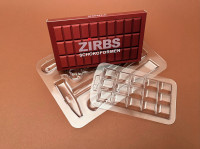

Zirbs has been producing chocolate moulds using the thermoforming process for two decades. Initially, the company mainly produced chocolate moulds made of PET thin film for various applications such as one-shot chocolates, broken chocolate or chocolate bars.

Since the early 2010s, bisphenol A (BPA) has increasingly become the focus of the packaging industry, particularly in connection with materials that come into direct contact with food. Due to its potential health risks, BPA has been banned as a plasticiser for food packaging in many European countries. This has fuelled the search for alternative materials that are both safe and sustainable.

PET offers promising properties here. The base material polyethylene is ‘hardened’ by the addition of terephthalic acid, so that the use of plasticisers such as BPA can be dispensed with. PET not only impresses with its mechanical properties, but also with its recyclability. PET can also be produced as bio-PET from renewable raw materials, which makes its use even more sustainable.

In 2023, Zirbs took over the chocolate mould production of the company Ruth from Bochum. This acquisition made it possible to further expand the production of durable chocolate moulds made from PET sheet material. The advantages of such production moulds have been proven over decades, particularly for small and medium series in chocolate production.

In view of the increasing demand for BPA-free alternatives, Zirbs is working intensively on the further development of these moulds in order to adapt them to the requirements of industrial production and the needs of medium-sized companies.

Cleaning is a key aspect in the use of PET. The maximum permissible continuous use temperature of 65 °C, as specified by the semi-finished product manufacturers, sets limits here. This requires careful adaptation of the cleaning processes in order to guarantee the longevity and functionality of the moulds.

Over the coming months, Zirbs plans to launch further developed mould sets on the market that meet the requirements for BPA-free materials and are also suitable for industrial production. The small and medium-series PET moulds already available form a solid basis for future innovations.

http://www.zirbs-verpackungen.de