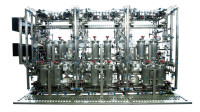

A large number of flavors and colorants are used in the production of colorful sweets – and have completely different physical properties. Natural and organic food colors in particular have a high viscosity of up to 3,000cps. If the metering technology used has small feed diameters, only a low flow rate is achieved, which quickly results in a high injection pressure of up to 45bar. However, the same systems must be able to process very liquid water-based colorants and flavors at high flow rates of up to 6,000 g/h. These challenges in the production of confectionery like lollipops or jelly sweets and other candies were increasingly pushing metering systems of one global candy manufacturer to its limits. The experts from Lewa Italy therefore developed a new solution with twelve individual single head pumps, each with its own electric stroke drive, with which six colors and just as many flavors of different viscosities and flow rates can be metered in parallel. Due to limited space within the production line, Lewa implemented the new system in a tight installation space of 2.8 m (length) to 1.2 m (width).

In order to guarantee the high quality of the colorful jelly sweets for every flavor, precision must not be compromised. For this reason, all twelve Lewa ecoflow metering pumps each have a separate electric stroke adjustment and an automated control circuit with the tried-and-tested Coriolis flow meter. As it no longer needs to be monitored and controlled manually, the system can easily run around the clock, up to seven days a week.